Capabilities

Materials

01 /

Material Expertise

Our primary plastic materials are HDPE, ABS, TPO and TPR resins. We have 11 large extruders, all with co-extrusion capability. Our main colors are Black, Grey, Tan, but we can process any color required. Our manufacturing capabilities for extrusion include thicknesses of 0.080” to 0.500”. Our material comes into the plant and all resins are tested by QA before being transferred into our silos. Resin blends are adjusted daily depending on the inventory in the plant.

Our wide selection of mild steel, stainless steel and aluminum along with TriEnda’s metal fabrication capabilities allow the production of complex metal designs. TriEnda’s vertically integrated manufacturing approach is ideal for hybrid material handling solutions that utilize both metal and plastic.

TRIENDA MATERIAL SELECTION OVERVIEW

HDPE

- High Density Polyethylene

- Up to .400″ Thick Sheet

- Textures Available (Levant, Seville, Haircell, Smooth)

- 100% Recyclable

- Proprietary TriEnda Resin Formula

ABS

- Acrylonitrile butadiene styrene

- Up to .400″ Thick Sheet

- Textures Available (Levant, Seville, Haircell, Smooth)

- Temperature and Humidity Controlled ABS storage

- Damage Resistant

METALS

- Mild Steel

- Stainless Steel

- Aluminum

- Tubing

- Sheet metal

- Round and Square Stock

02 /

Custom Coloring

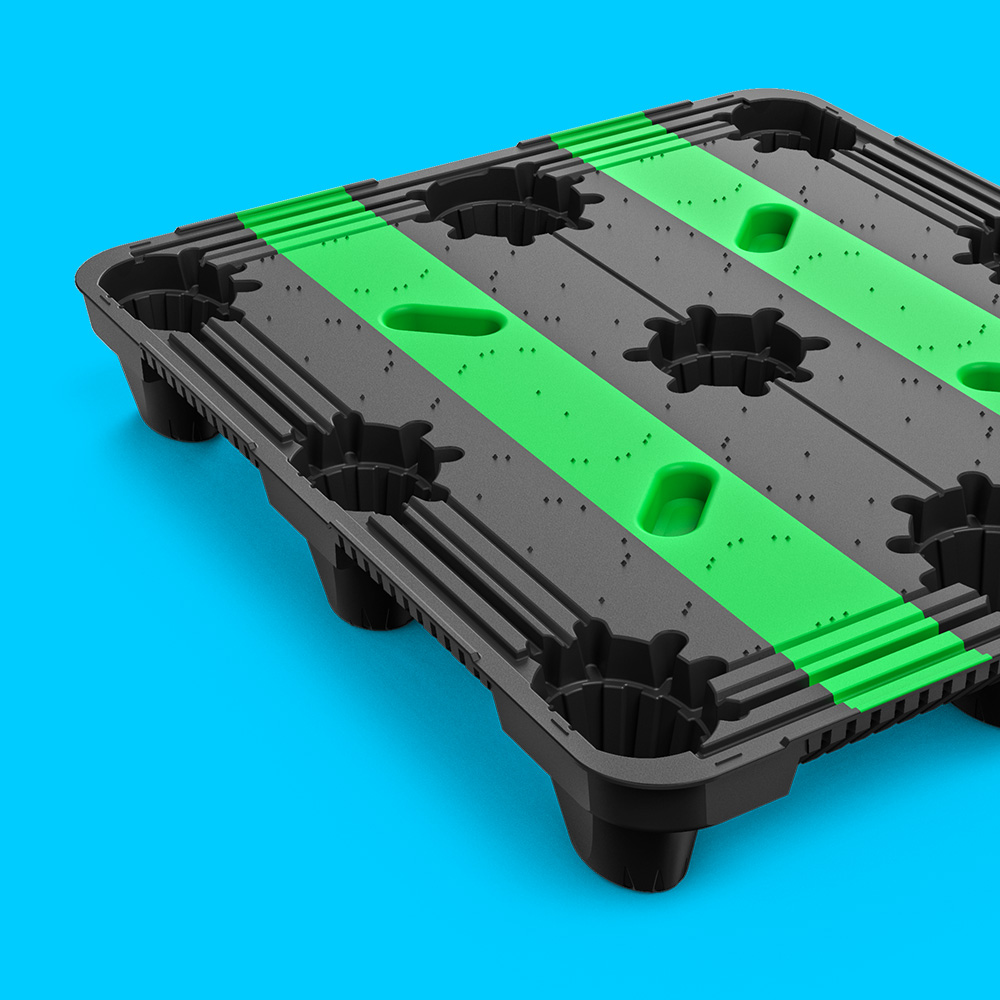

COLORED STRIPE

Custom stripe colors are co-extruded onto plastic sheeting during the extrusion process. Welded on colored material ensures lasting, brilliant colors for easy visual identification.

FUSION LABELING

TriEnda utilizes polymer fusion labeling technology that bonds labels to your thermoformed part at the molecular level. This durable solution permanently fuses full-color labels onto TriEnda’s thermoformed plastic solutions, resulting in a vibrant decal that resists environmental and physical damage.