Custom Thermoforming

Products and Solutions

01 /

Our Expertise

As a groundbreaking leader in material handling solutions and custom products for more than 40 years, we are continually innovating to deliver the highest-quality custom thermoformed products.

Our in-house custom thermoforming fabrication process involves heating an extruded sheet of our proprietary resin blend until it is soft, and then stretching it over a male or female mold, leaving it to cool until formed.

- The single sheet thermoforming process involves heating one sheet and placing it over the mold.

- The twin sheet thermoforming process involves heating two sheets on two individual molds, and bonding them together before they harden, creating a lightweight yet an extremely strong and high-performing product.

Why Custom Thermoforming?

The Scope

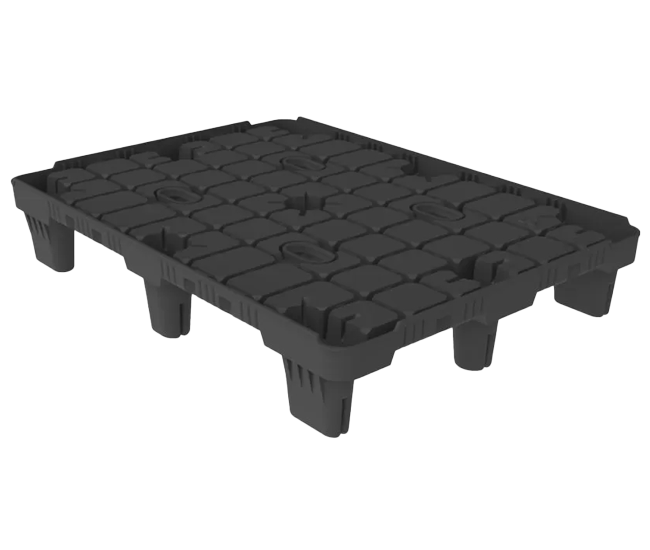

The wide variety of high-quality, dependable custom products constructed using single sheet and twin sheet thermoforming include:

PRODUCTION FACILITY

Benefits

There are many benefits to using custom thermoformed plastics when compared with other materials and fabrication methods, including:

- Reduced prototyping costs

- Reduced tooling costs

- Reduced material costs

- Higher quality and more durable

- Optimized for weight and performance

- Overall weight reduction

- Faster time to market

- Ability to modify designs, including color and texture

- Fewer harmful VOCs

02 /

Advantages

Efficiency

Speed

Trusted Leader

We are a trusted global leader in custom thermoforming and sheet extrusion. Contact us online to learn more about our advanced material handling solutions. Our sales team can help you begin exploring our extensive catalog of products and custom design capabilities.